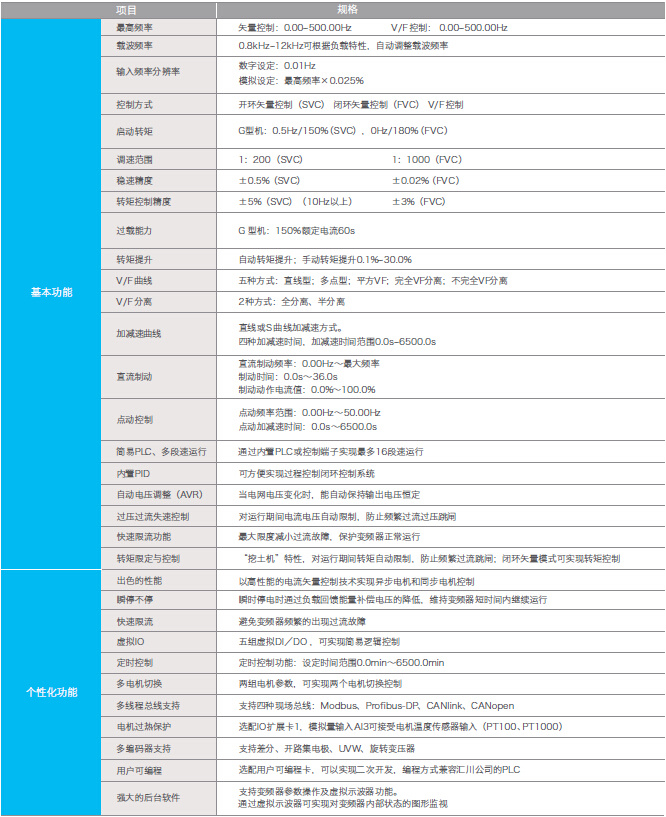

Synchronizer Driver-MD500E

Product Description

Product Details

The performance of the MD500E series is the same as that of the MD500 series. The main differences are as follows:

·MD500E series inverter can realize encoderless synchronous motor control, making synchronous motor control popular.

·It can accurately identify the parameters of asynchronous induction motor and permanent magnet synchronous motor (MD500E series), and realize high-performance vector control;

MD500 is a high-performance inverter that integrates the vector inverter technology of Inovance Technology. While maintaining excellent basic performance and functions, the MD500 inverter can easily face the technical and performance problems encountered in various industries and equipment so far, and from the customer's point of view, the ease of use, feasibility Significant improvements have been made in terms of maintainability, environmental friendliness, reduced installation space and compliance with higher design standards.

High performance, high quality, small installation area, high power density design, more in line with the user's personal experience;

It is the main model of Inovance's new generation of inverters. With high-performance current vector technology, it can easily drive induction motors and meet the working requirements in various environments;

·High-standard design in the industry, based on years of accumulated experience in multi-industry applications and persistent pursuit and leadership of drive technology.

|

compact |

Excellent performance |

High reliability |

Ease of use |

|

Optimized structural design, leading technology platform |

High speed stabilization accuracy and wide speed regulation range |

Overall thermal reliability |

Instantaneous stop and non-stop function |

|

Built-in DC reactor |

High-speed output under vector control |

Temperature rise test of the whole machine |

Overexcitation function |

|

Perfect brake circuit solution |

Large torque at low speed, small torque ripple |

Three-proof paint automatic spraying process |

Achieving complete and semi-separation of VF |

|

Various motor drives |

Large margin derating design |

Energy-saving application of fans and pumps |

|

|

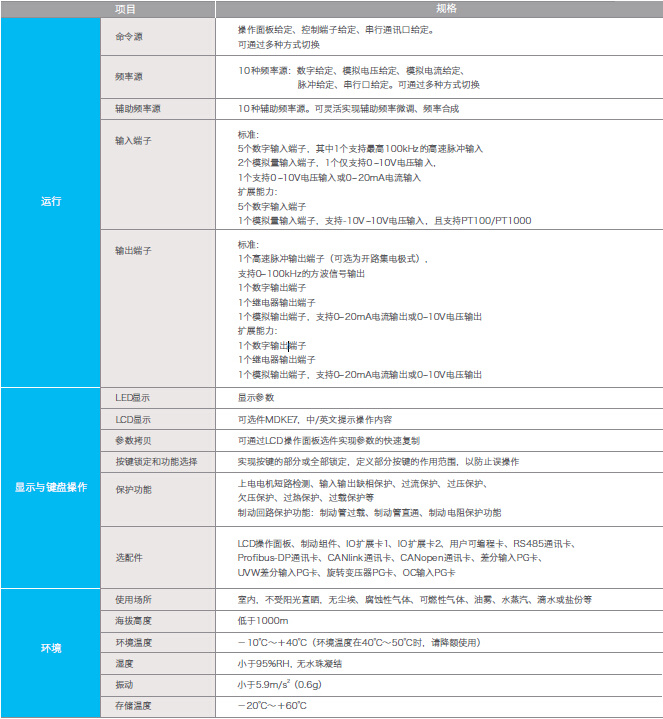

Support a variety of PG cards |

long life design |

The terminal functions are flexible and diverse, |

|

|

High accuracy of self-tuning motor parameters |

Independent air duct design |

more comfortable to use |

|

|

in line with international standards |

Flexible application of communication interface |

||

|

Wide voltage input range |

Built-in adaptive PID function module |

||

|

EMC design specification improvement |

Support InoDriverShop background software |

||

|

Meet CE certification |

User programmable card |

||

|

Meet ROHS Directive |

The protection of the whole machine is more perfect |